Parylene AF4 polymers: TheUltimate Solution For Your Homes

The parylene coating process

includes the vaporization and polymerization of dimers. Parylene coating is

very thin and painted deep in circuit boards. It has a thickness and uniformity

which makes it in demand in the market. It offers an even and smooth surface,

unlike the roughness of the conventional coating. Convent I ok nal coating has

an uneven thickness film which is unable to form with the contour of the shape.

It has its application in a great list. It is applied in the medical field in

stents, pressure sensors, and in numerous other equipments. In the electronic

field, it is used in the medical PCBA and military PCBA. It can be used in

rubber or silicone. Parylene is safe because of its chemical inertness and

hydrophobic properties. They protect the device as well as the body in which it

is implanted, which is one of its greatest features.

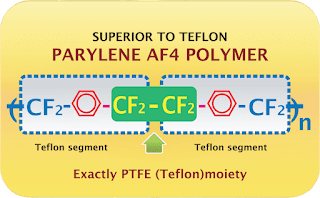

Why Parylene AF4?

They prevent corrosion and provide chemical resistance. It's pinhole free and conformal. Also, the parylene AF4 polymers are stable physically and chemically. They are moisture-proof, waterproof, anti-corrosion, and have salt spray. Their major attraction is that it protects from contaminants, solvents, and corrosive vapors. Another doesn't have issues like sagging, thinning out, and other defects found in n conventional coating. Parylene is stress-free to use for its safety and countless advantages. They are widely used in the aerospace, automotive, medical field, semiconductors, and electronic items. They are inert which explains why they are safe to use. Parylene AF4 is superior to most liquid-based coatings like acrylic or silicones due to its structure and premium quality.

They are used in almost all fields and have created a revolution in the industry. They are in high demand globally and industries are opting the products from the best companies. Parylene also protects electronic components. They can be used to coat all kinds of surfaces like round, flat, and so on.

Another advantage is that they won't increase the

weight of the device. They have the highest purity in the markets.

- Their low water absorption is a great quality that helps with the parylene coating process.

- High dielectric strength can become useful when it comes to

electronic components.

- Biocompatibility

- Extend the PCB life.

- They also reduce the substrate interface ionic conduction.

- Offers high resistance to solvents, chemicals, and fungi. This

property is essential to regions with more humidity and moisture.

- Transportation and defense are the other fields where the Parylene AF4 polymers are

used.

Nano Ceramic Coating and its Uses

They can be used to coat cars, houses, marine ships, and so on. They give a glazing effect which is a unique property. This makes it in high demand in the markets. They are scratch-resistant too. They offer products that have long-term durability for more than two years. They offer a superior quality coating and give a luxurious effect to your homes and vehicles. It has a protective thin layer and is available at the best rate. They also prevent UV damage and oxidation. Coatings chemical suppliers are available online at different price ranges.

Comments

Post a Comment